How to address safety and sustainability dimensions in new high-performing biobased coatings?

That’s what we are working on in BIORING, and to better answer we hold our first Open Innovation Workshop, titled Early sustainability assessment in innovation process. Share good practices on anticipatory risk assessment, prospective, ex-ante LCA and more.

We gathered several experts in SSbD, LCA, chemicals, materials and process design & modelling, and data analytics for an open discussion on methods, tools, data and case studies. The starting point was the BIORING anticipatory approach in the evaluation of potential product development and life cycle impacts, and the challenges we are facing in the development of our sustainable biobased coatings for high-demanding applications.

After a brief presentation of the project and its objectives, we introduced our approach for the BIORING early sustainability assessment, providing highlights on the LCA, foresight tools, and design & process modelling applications.

In order to discuss, explore and share experiences on these main aspects/challenges, participants were divided into three groups concerning:

- Challenges of early assessment.

- Assessment & foresight tools.

- Process and design modelling.

Highlights from the community

The first group faced the problem of lack of information at the early stage of the innovation process. On this concern, look carefully at the process and its upscaling since the very begin, estimate impacts and have a clear question to answer before starting the analysis, have been proposed as good practices and widely shared. As well, since dealing with chemicals could bring high level of uncertainty in risk assessment, even when considering similarity within similar molecule families, focus only on components that are used in significant quantities and apply machine learning are viable solutions. In this context, performing a qualitative LCA at the beginning of the material development could provide a useful starting point to share early on with industrial partners, to detect right away deviations from reality, and promote communication among them.

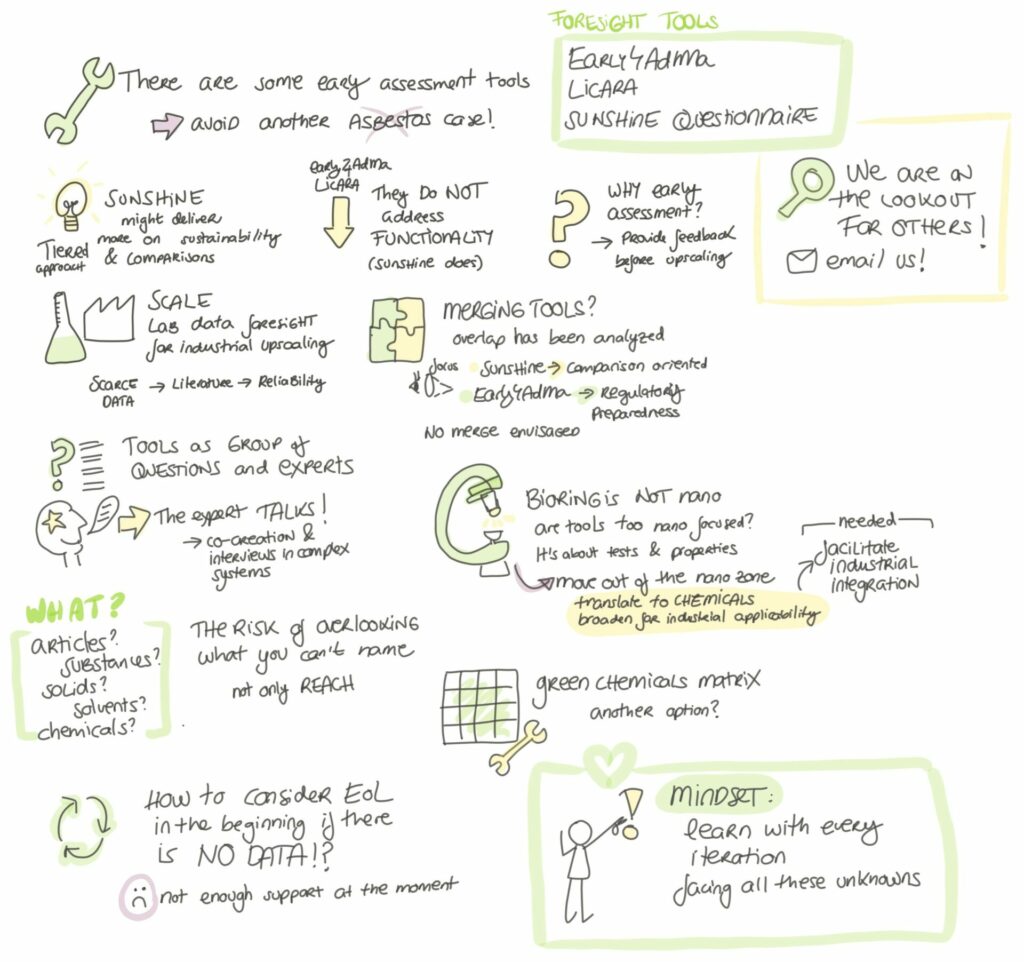

The second group discussed about foresight tools, proposing some options like the SUNSHINE questionnaire, but with the need of moving out from the nanotechnology framework in favour of the chemistry one. Moreover, talks and meetings with experts have been proposed as valuable alternative or complement to these tools, in a co-creation perspective. Indeed, considering that in BIORING we still have to face data gap (e.g. in the End-of-Life), and that different tools don’t allow merging data with one another, the best mindset should be to use several options, like tools and expert meetings, to face all these unknowns.

The third group dealt with some issue of open-source modelling software, often the only ones economically affordable for bio-companies: their reliability is inconstant, mainly due to the problem of transferring and translating data from a platform to another one. Integrate process modelling with LCA was another challenge highlighted, to be addressed most likely defining optimization parameters using both quantitative and qualitative data. But which data? There could be a gap between your needs and data available in software’s databases, that may not include the substance you’re working with (like lignin for BIORING): this could become a good opportunity for data mining. Overall, working with databases owners and companies is almost mandatory; thus, a common exchange format for all kind of process data would be ideal.